In construction, the personnel at the site can make or break the project. This means that skilled site management and trade crews are in high demand. In modern construction, where buildings have become more complex, the role of the team’s experience has actually grown.

This creates a major challenge: we can’t always guarantee we have the same people available in all our projects. To ensure that the scope, cost, and time remain within set goals and requirements, we need to standardize the construction processes so that even less-experienced teams have a chance to succeed.

To achieve this, it is absolutely necessary to have a shared understanding of what has to happen, when, and where. This makes the schedule the backbone of any construction site: It has the power to guide the entire team, from management to all crew members and off-site stakeholders from design to logistics deliveries. With proper schedule management, production flows smoothly without interruptions or conflicts and the project will be delivered on time, in quality, and on budget – or even exceeding expectations on these.

However, getting started can be challenging: the various terms and methods of construction scheduling can get confusing if you are not familiar with them. Hopefully, this article shines a bit of light on these and helps you to choose the right method for scheduling your sites.

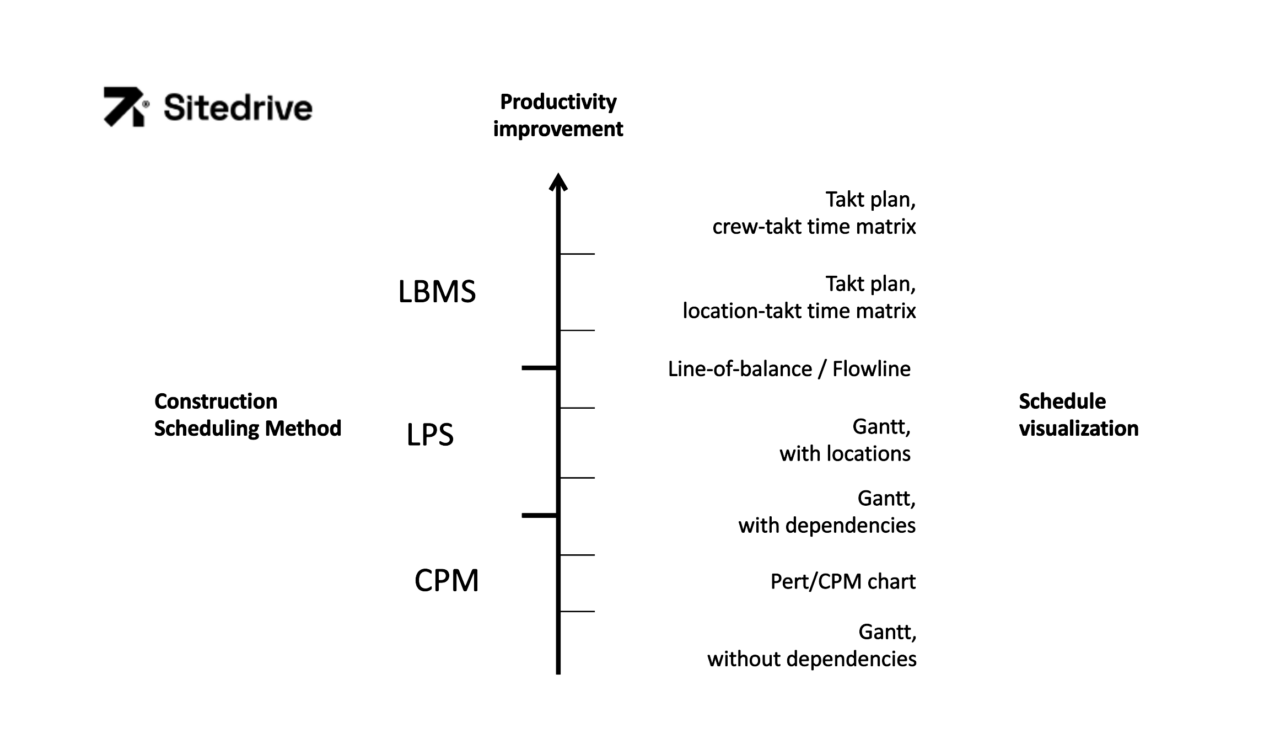

We’ll explain the three most popular construction scheduling methods: the Critical Path Method (CPM), the Last Planner System (LPS), and the Location-Based Management System (LBMS).

Let’s delve into these a bit closer. ⬇️

CPM scheduling in construction

CPM, which stands for Critical Path method, is the most widely adopted scheduling method in construction. And no wonder: it is an effective technique to identify the shortest and fastest path to complete a project.

CPM guides the schedule planner to map out the dependencies between different tasks. With predecessor and successor and their relationships finish to start, start to start, finish to finish, and start to finish. It allows the project schedules to be managed in detail.

However, thanks to the complexity of buildings, it’s easy to get tangled in all the interconnected dependencies. Additionally, communicating specific tasks to workers using CPM charts is hard.

Last planner system in construction

The Last Planner System is a broader concept than the CPM and it emphasizes collaboration. It is often used in larger construction projects where good communication and teamwork are essential.

This method uses pull planning logic where the project schedule is refined continuously. The process consists of four levels which should ideally be refined with the project managers, the superintendents, and the trade crews who have first-hand knowledge about the work. Refining the schedules with the trade crews utilizes collective knowledge and increases crew-level commitment.

This is what the process looks like:

#1 Master planning. Overall schedule with essential milestones.

#2 Phase scheduling. Dividing the master schedule into separate phases and detailing phase-specific schedules.

#3 Lookahead planning. Refining phase schedules for example to month-level accuracy.

#4 Weekly planning. Final refinement of tasks that are performed next.

The site performance is measured with the percent plan complete (PPC) which tells how much of the planned work was actually completed.

The LPS is often referred to as a lean construction method as it increases productivity significantly, delivering projects cost-effectively and on time.

Even though LPS might seem like a solution to all our problems it still has a few shortcomings.

For example, the constant refinement of the schedule means you won’t have a detailed view of what happens further down the line, and sometimes tasks might get settled only a few days before they should be executed.

This creates a challenge, as construction is often performed by subcontractor crews and they rarely have time to wait unless, of course, you pay them to be idle. If there are larger interruptions for the subs, it’s understandable they will want to move to another site where they have work waiting for them. Additionally, if the site does not have clear times set for the assembly tasks they have to have proper material buffers in place to ensure that materials will be ready when the work starts. Again managing this requires extra work and extra costs which equals to waste.

This is why you should have proper resource buffers in place: this way the workers and the materials are available when the tasks need to be completed.

Additionally, the schedule refinement has tremendous not-so-ideal effects on the supply chain such as uncertainty in capacity planning for the material manufacturing facilities. But that is a whole other story.

>> Read more about the process of weekly planning

Location-Based Management System in construction: TAKT

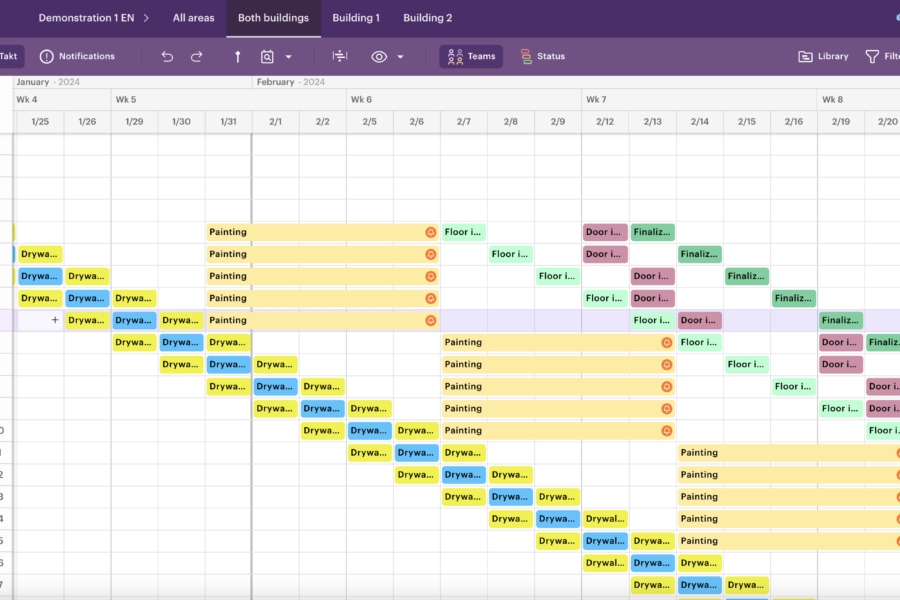

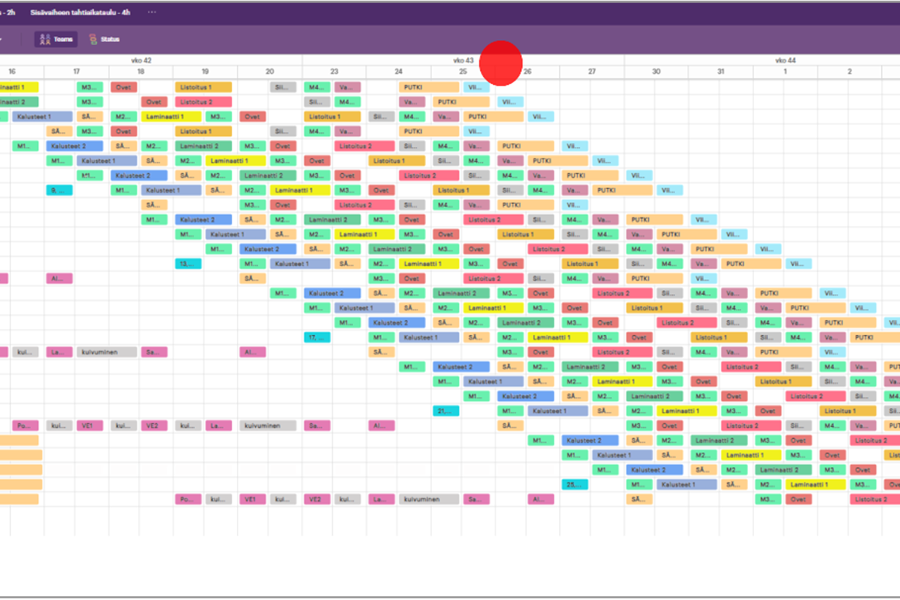

In location-based planning methods, schedule planning is centered around different work areas on the site. It starts with mapping out different locations and identifying the work phases, tasks, resources, and materials needed to complete them.

This means that all tasks are linked to a specific location. Through this, relationships and dependencies between different tasks become self-evident.

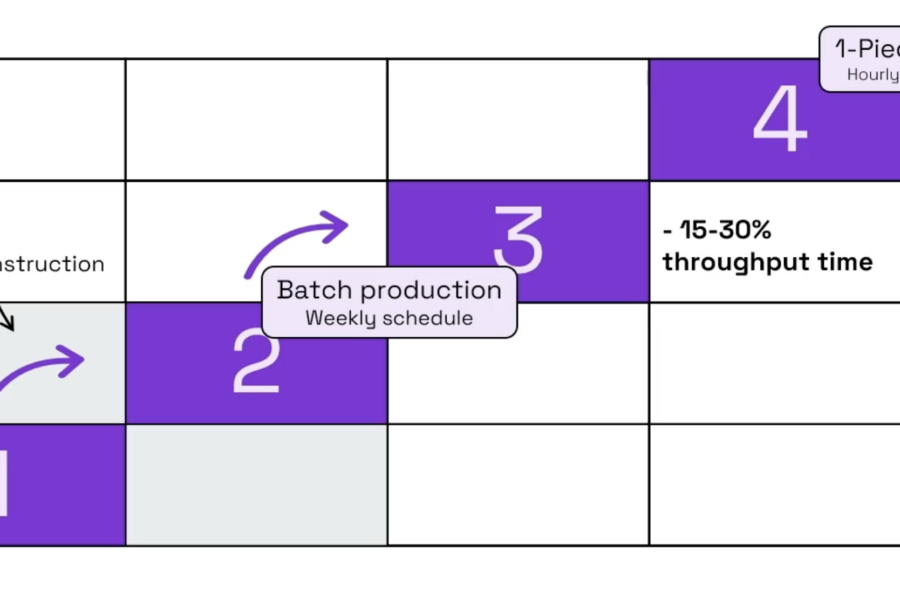

The latest evolution of the location-based methods is takt production. Takt methods include takt planning and takt production control.

In brief, takt planning is all about identifying location-specific tasks and the right order to execute them. Tasks are then grouped into work packages based on the skills needed to complete them.

Ideally, grouping of the tasks is done so that a work package contains only the tasks that can be performed uninterruptedly within a location.

After this, the work packages are combined into a work sequence (=takt train) that flows through the locations and forms the schedule of the site.

Here a task means a specific activity such as

- verify the quality of materials

- measure to verify the installation location

- cut material to the right size or

- install material to its place.

Whereas the work package is the grouping item such as “Install lowered ceiling”

The strength but maybe also the weakness of location-based and takt methods is that they work best in projects with multiple similar locations and repetitive tasks. Although takt production can be used in other cases, you need bigger buffers to succeed. In such cases, the project can actually often benefit more from using the Last Planner System.

Tips on how to choose the right method for your project

There is one critical weakness in all these construction scheduling methods: they usually rely on imaginary units that are only loosely related to the actual activities at the site. And yes, although combining action into work packages and contracts is essential, as long as they lack a relationship to actual activities and materials, they are just summaries of work without actual content. For example, if you don’t know what exact components are needed to install a lower roof frame, you can’t truly know what the execution requires. In these cases, the worker has to make the final decisions and again, it comes down to individual skills, not standardized processes.

Among the various scheduling methods, takt planning can provide the most suitable information for production control.

However, planning everything in detail might not be possible in some cases where for example the scope still changes, the city code demands changes, the supplier is not able to provide components, or there are other disruptions and modifications.

This is why we suggest using best practices of multiple methods based on project type and goals. Also, the site team’s skill level has to be considered: there is no point in demanding something if other parties think that some other method would lead to better results and won’t commit.

In short: LPS with location-based Gantts is great for everything that cannot be planned in detail in advance. Takt suits the best situations with repetitive work that can be planned in necessary detail.

Are you developing your construction projects’ schedule planning and management?

Check out this comprehensive guide for construction scheduling

Or get direct help from our experts and

Contact us here