On average, it takes 16 to 20 months to build an apartment building with more than 10 units.

That is already a pretty good pace, right? But what if you could go from good to great and start building much faster, so that same project would take only 10 to 12 months? Some construction companies are already achieving this by using lean construction methods.

If you’re interested in getting the same results, continue scrolling. We’ll cover the basics of lean construction and share practical tips and examples that help you master lean.

Start here. 👇

What is Lean Construction?

Lean construction is a project management method that aims to shorten construction times by minimizing waste.

The goal is to identify unnecessary work, storage, costs, waiting times, movement, and mistakes – and get rid of these.

Lean construction is based on lean practices that were developed by Toyota in the 1950s. Lean manufacturing was the answer to the changing demand and a way to bring productivity up.

The construction industry is now facing a similar shift. The building productivity has remained on the same level for the past 40 years, but the expenses have not. The rising cost of materials and increasing inflation are forcing the developers and construction companies to act.

Industrial, lean construction is a straightforward solution to this. It helps us to see the building as the product and work sites as the factories producing them. 🏢

Lean construction principles

The core principle of lean construction is removing waste in all its forms, including time, resources, and effort. It emphasizes creating value for the customer while reducing non-value-added activities. Lean construction encourages collaboration, continuous improvement, and a focus on the flow of work.

Key principles of lean construction include:

- Value stream mapping: Identifying and delivering what the customer values the most. Getting rid of activities that do not contribute to that value.

- Elimination of waste: Minimizing waste through careful planning, efficient processes, and reducing unnecessary activities, such as waiting, overproduction, excess inventory, and rework.

- Continuous flow: Ensuring a smooth and continuous flow of work throughout the construction process, avoiding delays and bottlenecks.

- Pull planning: Involving all project stakeholders, including contractors, subcontractors, and suppliers, in the planning process. Aligning their efforts and establishing realistic timelines.

- Last Planner System: Breaking the project down into more manageable tasks and involving the workers executing them in the planning process. This increases accountability and helps identify and resolve issues in real-time.

- Visual management: Using visual tools, such as Kanban boards, to make progress, bottlenecks, and potential problems visible to all team members.

- Continuous improvement: Encouraging a culture of learning, feedback, and innovation to identify areas for improvement. Implementing changes that lead to better efficiency and quality.

The implementation of lean construction requires a collaborative and open-minded approach from all project stakeholders. You need to be willing to make a shift in mindset and challenge traditional construction practices.

👉 Dive deeper into the lean construction principles here

Lean construction benefits

Most importantly, lean construction typically results in 30-40% shorter construction times and significant cost savings. On top of that, it offers other major advantages for your site management and crew:

✅ Everyone knows what needs to happen, when, and where. Each member of your crew has a list of tasks they need to complete during the ongoing week, day, or even hour.

✅ More meaningful work. The goal is not to work harder but much smarter. Construction at its current state is overloading, leaving room for mistakes and burn-outs. Lean construction brings clarity and removes unnecessary hassle from your sites.

✅ More collaboration. The idea is not to manage from the top down but to get the crew’s input on where there is waste.

✅ Better communication throughout the worksite. Lean construction increases transparency and helps build trust throughout the site. You have a clear structure and routines everyone has agreed to follow.

✅ Increase in quality. In our experience, there are fewer mistakes on lean construction sites. The clear, organized structure doesn’t leave as much room for guesswork and mistakes.

Lean construction examples

Here is one example of what lean construction looks like at its best.

Challenge: A Finnish construction company Fira wanted to remove unexpected surprises, delays, and costs from their pipeline renovations.

Solution:

- Detailed planning of production, taking into account scheduling and material logistics.

- Takt production.

- Lean construction software, Sitedrive, allowed for planning and managing schedules at an activity level.

- Preparing materials beforehand.

- Monitoring the conditions of the site with sensors.

End result: Fira built each bathroom from concrete to done in just two weeks.

👉 Read the full case study and watch a video showcasing the progress

👉 Are you ready to achieve the same? Get a demo of Sitedrive and start managing your site with lean construction practices.

Lean construction process management

Here are some essential steps to manage a lean construction process:

- Establish a Clear Vision. Define the project objectives, including the desired outcomes, customer value, and key performance indicators (KPIs). Ensure that all project stakeholders share a common understanding of the project goals and the importance of lean principles.

- Start Collaborative Planning. Engage all project stakeholders, including contractors, subcontractors, suppliers, and designers, in the planning process. Use techniques like pull planning and the Last Planner System to develop a detailed construction. The goal is to optimize your workflow and identify potential bottlenecks and dependencies.

- Conduct a Value Stream Mapping Exercise. Identify all the activities involved in the construction process, from design to completion. Analyze each step to determine its value addition, waste, and opportunities for improvement. This exercise helps you to visualize the entire process and identify areas for lean implementation.

- Foster a Culture of Continuous Improvement. Encourage regular feedback, share lessons learned, and empower workers to identify improvement areas. Promote open communication channels and a willingness to experiment with new ideas and approaches.

- Establish Standardized Work Procedures and Best Practices. Eliminate variation, reduce errors, and enhance efficiency. Document the standard processes for different construction tasks and ensure that all team members are trained to follow them.

- Utilize Visual Management Techniques. Make project progress, workflow, and potential issues easily visible using tools like Kanban boards, visual dashboards, and information displays. Keep the entire team informed about the status of tasks, milestones, and potential obstacles.

- Create Continuous Flow and Pull Systems. Emphasize the importance of uninterrupted work and avoiding delays. Implement pull systems, where tasks are released based on demand and capacity, to prevent overproduction and minimize inventory. Reduce waiting time between activities by carefully sequencing work and reducing dependencies.

- Identify and Eliminate Waste in the Construction Process. Common sources of waste include excessive production, excessive inventory, transportation, motion waste, waiting time, defects, and unused talent. Regularly analyze processes and take proactive measures to reduce or eliminate these forms of waste.

- Collaborate with Suppliers. Engage suppliers and subcontractors early in the project and involve them in the lean process. Encourage collaboration, share information, and establish mutually beneficial relationships to optimize the supply chain and ensure timely delivery of materials and services.

- Make Data-Driven Decisions. Collect and analyze data related to project performance, productivity, and quality. Use this information to make informed decisions, identify improvement opportunities, and monitor progress toward lean goals.

- Leverage technology and digital tools. Capture and analyze data effectively.

Remember that managing a lean construction process requires commitment, collaboration, and continuous learning. It’s an iterative process that involves adapting and refining practices based on feedback and results.

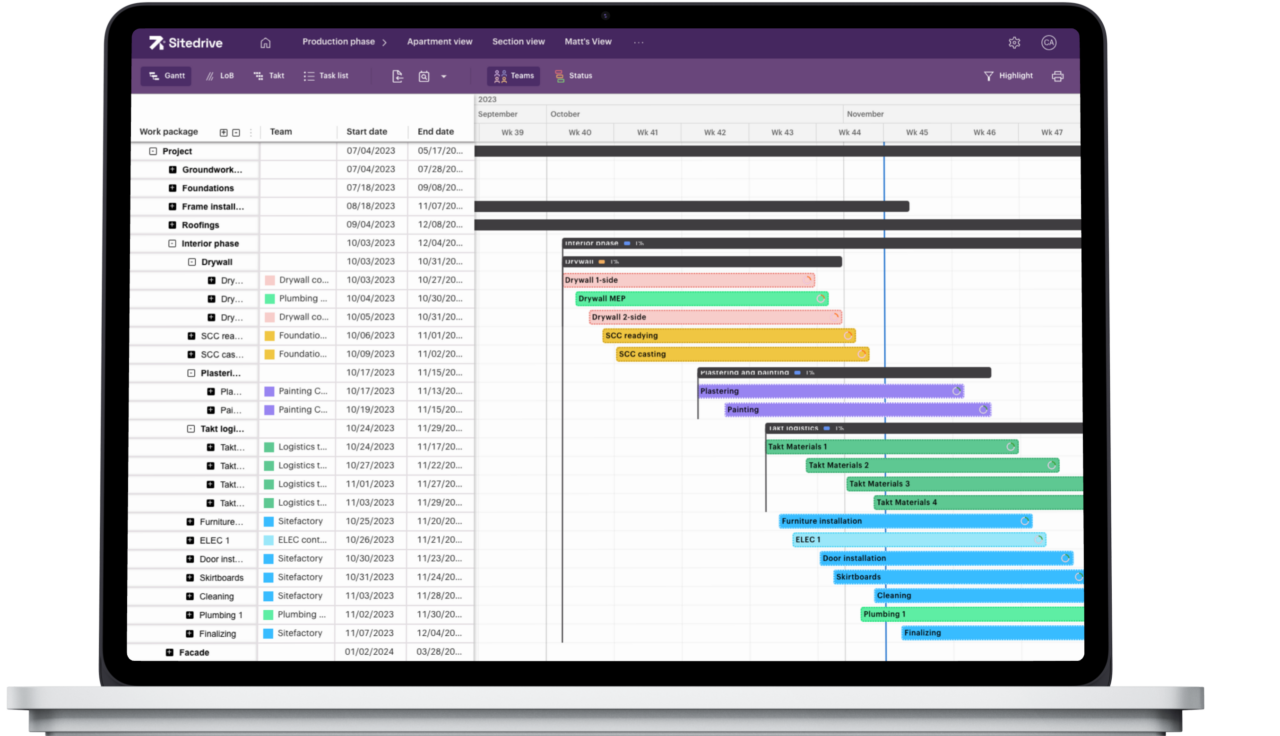

Lean construction tools

You can’t execute lean construction with just pen and paper. The digital tool helps you to plan on a more accurate level, identify waste, and gather data for continuous improvement.

Get familiar with lean construction software: book a demo of Sitedrive

Lean construction training: Should you get external support for your lean construction management?

You should consider external lean construction training to support you in the following situations:

- Lack of specific expertise with a proven track record. If you don’t have experience in lean construction management, outsourcing will provide access to specialized knowledge and skills. With Sitedrive and its experts, you can start building the lean principles into your organization. We help you implement them and maximize the benefits.

- Limited Internal Resources. Implementing lean construction requires dedicated resources, including time, personnel, and digital tools. If you have limited internal resources available for lean construction management, we are here to help.

- Time Constraints. If you are working on a tight schedule, we can help accelerate the process. Our experts can quickly mobilize and implement lean practices, reducing the learning curve and ensuring timely project delivery. We have examples where we cut a residential building construction time to 1.5 months in our first project.

- Change Management. Implementing lean construction involves significant changes in organizational culture, practices, and workflows, and it can create resistance to change. You will most likely benefit from an external perspective and expertise to facilitate the transformation.

- Pilot Projects. If you want to test lean construction on a specific project, you probably want to see the benefits fast. Engaging experts allows you to test the effectiveness of lean practices without committing long-term.

Ultimately, you should define a need for external training through your company’s strategic objectives and a cost-benefit analysis.

Need help? Get in touch with our lean consultants!

Lean construction implementation guidelines

Are you ready to dive deeper into lean practices? Takt production helps you to bring lean practices into your site.

Read more about the basics of Takt production

And download this practical handbook that helps you implement Takt production successfully. Download the guide here