Lean construction is about improving productivity by continuously learning about the construction process and removing waste and roadblocks slowing it down. Here are the 7 lean construction principles which help your construction projects run smoothly.

📚 Want a quick overview of Lean Construction in a few minutes? Read this Introduction to Lean Construction

#1 Keep things moving on a Continuous Flow

In lean construction, continuous flow means ensuring that every part of the building process moves to the next one smoothly. Work keeps going at a steady pace, with no hold-ups.

The goal is for each task to flow into the next one without delays. This means you must understand the building process and plan it carefully so everyone knows what to do and when.

#2 Eliminate waste to get rid of things that slow you down

Cutting out waste is vital to making your project more efficient. Lean construction highlights eight main types of waste you should watch out for:

♻️ Overproduction: Doing more than needed. Someone spends too much time or resources on a task or polishes something further than necessary and planned.

♻️ Waiting: This happens when work pauses for reasons unrelated to the worker. They might have to wait for materials to arrive or for another job to finish.

♻️ Transportation: Moving materials, tools, or other items from one spot to another or out of the way.

♻️ Overprocessing: Repeating something constantly. For example, double-checking the work quality more times than is needed. The aim is to do the work right the first time instead of having to do excessive checks.

♻️ Unused creativity: Not using good ideas that could make the work easier or faster.

♻️ Movement: Moving from one location to another without a good reason. For example, going to check if a new area is available for work, only to find out another task is still in progress.

♻️ Mistakes: Errors that require doing the job again. A classic example of this is tasks done in the wrong order or not right the first time. Meaning something has to be deconstructed and done again.

♻️ Storage: Keeping more materials on hand than you need. For example, ordering materials too early leads to clutter. Waste in storage tends to hide and cause other waste.

#3 Collaborate to succeed with Pull Planning

You should involve all stakeholders in planning the project, including contractors, subcontractors, and suppliers. With everyone’s input you will end up with a more realistic plan and are less likely to run into problems.

#4 Break it down with the Last Planner System

Here’s a simple rule of thumb: the smaller the tasks, the better the production flows.

The Last Planner System aims to break the project plan down into smaller, more manageable tasks with the help of people who are actually doing the work. Crew members, such as carpenters, electricians, and plumbers, share the steps required for finalizing a specific area.

It helps you better understand how long different tasks actually take and in what order they need to be completed. Thus, you can make a more accurate plan with more realistic deadlines.

This type of collaboration also increases accountability, ensures everyone knows their part, and helps to identify and resolve issues in real-time.

#5 Use visual management

It’s impossible to execute lean construction without visual management. Using tools like Kanban boards to show what’s happening on the project helps everyone stay on the same page. It also makes it easier to see progress and spot roadblocks and other issues.

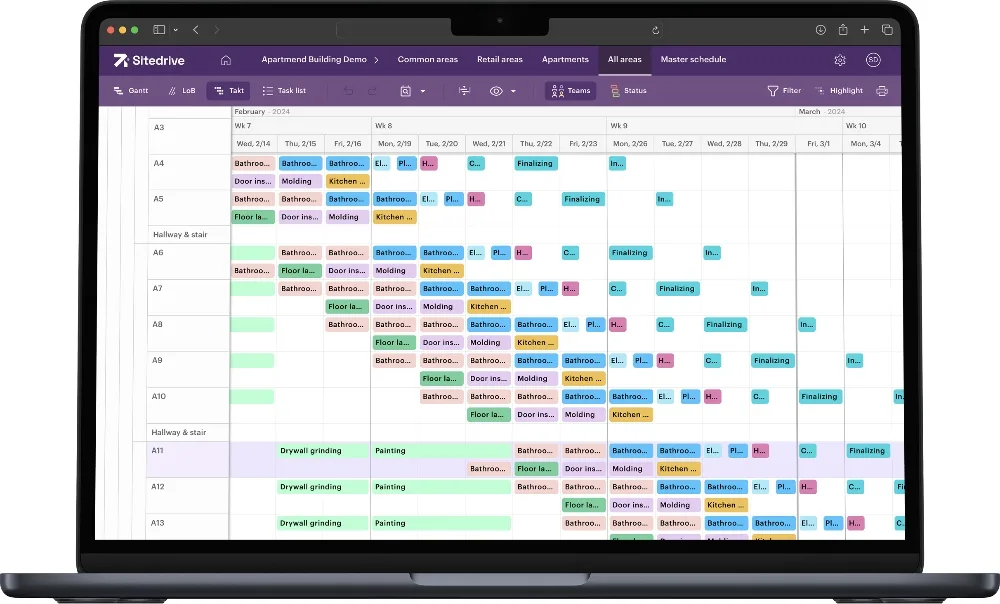

Here’s an example of how lean construction software Sitedrive visualizes the tasks on site with a Takt view 👇

#6 Keep getting better with Continuous Improvement

Lean construction is all about always looking for ways to do things better, faster, and higher-quality. You should aim to learn and use that knowledge to improve on the next location or job. You can do this with:

- Good documentation and data collection. Ensure information on roadblocks, delays, and execution times is stored in a digital, standardized format.

- A culture of learning, feedback, and innovation. When someone spots an issue, it should always be a good thing, as it helps you identify areas for improvement.

#7 Focus on what matters with Value Stream Mapping

Value stream mapping is typically used to identify bottlenecks in the main value stream of a company. Basically, it is a fancy way of saying, “Figure out what brings value to the customer and focus on that.”

The main outcome should be a better cross-organizational understanding of:

- How value is delivered?

- Where calendar time is lost and errors are made?

Value stream mapping is one of the less utilized tools in construction. Still it can be impactful in reducing waste of time in tendering, project preparation, and project planning. Traditional process mapping often serves the production phase of a construction project better, but value stream mapping has its place in finding the low-hanging fruits.

Implement Lean Construction Principles to Your Sites

These principles can help make construction projects run smoother and more efficiently. We have a guide to help you apply these ideas to your projects.

Our Practical Handbook for Takt Production helps you implement lean construction management through Takt.